PRODUCT DESCRIPTION:

The UHMWPE fender is a unique product of wharf and port, which primarily decreases the shear force on the fender and extends its service life when ships berth at the shore. Large ports and wharves are used now, and the essential thing is to utilize the fender panel with reasonable wear resistance and impact resistance.

UHMWPE fenders demonstrate expertise as marine protection tools through their exceptional combination of strength and impact resistance, together with their low friction characteristics. The harsh marine conditions do not affect these durable fenders because they feature the superior strength of UHMWPE compared to existing rubber and timber options.

The excellent resistance of UHMWPE fenders protects them from UV rays in addition to chemicals and corrosion while requiring minimal maintenance. Vessels experience minimized wear because of their low-friction surface, which makes these products excellent for port facilities, piers, and offshore installations. Absolute durability and light weight are two features of this material that enable it to absorb energy effectively while protecting both ships and marine structures from harm.

Industry-Specific Names

Marine fenders play a critical role in protecting boats, docks, and harbors. They’re often referred to as dock fenders, boat fenders, or rubber marine bumpers. Other common names include wharf fenders, vessel fenders, port fenders, ship fenders, and marine dock bumpers. These fenders act as a cushion between vessels and dock structures, reducing the risk of damage during mooring or docking operations.

Where should be applied the UHMWPE Fender Facing Pad:

- 1. Marine & Jetty fenders front panel

- 2. Quay wall protection

- 3. High-speed conveyors

- 4. Bumpers

- 5. Pile guards

- 6. Wear Strips

- 7. Guide rails

What Makes UHMWPE Fenders Special?

The unique properties of UHMWPE fenders include strong material construction combined with little resistance and powerful impact protection. These fenders stay corrosion-free and hold up well against both sunlight and weight, so marine areas need no other protection. These fenders need low upkeep while giving extended durability to shield vessels effectively at reduced berthing costs—the company Diode Trading EST supplies UHMWPE fenders that perform effectively in marine safety applications.

Fenders

A fender is a bumper designed to absorb the kinetic energy of a vessel or a boat when berthing against a jetty, quay wall, or another ship. Fenders help prevent damage to boats, vessels, and berthing structures. They are usually made from rubber, foam, elastomer, or plastic. Rubber fenders are typically produced either by extrusion or by molding.

A suitable fender for a specific application depends on several factors, including the vessel’s dimensions and displacements, tidal variations, the maximum allowable stand-off distance, and the berthing structure.

The fender unit’s size is based on the vessel’s berthing energy. The energy of the berthing ship is related to the square of the berthing velocity. Marine fenders are used at docks on quay walls, ports, and other berthing structures. These fenders absorb the kinetic energy of a berthing vessel, thereby preventing damage to the ship or the berthing structure.

Floating fenders, such as elastomer and pneumatic fenders, are used for bunkering operations between two vessels. The fenders typically used on tugboats, recreational boats, ferries, passenger vessels, naval vessels, and luxury boats are boat fenders. These fenders are available in various types, including square fenders, ‘D’ fenders, keyhole fenders, and wing fenders.

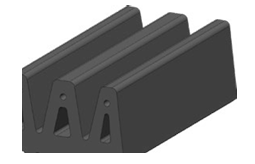

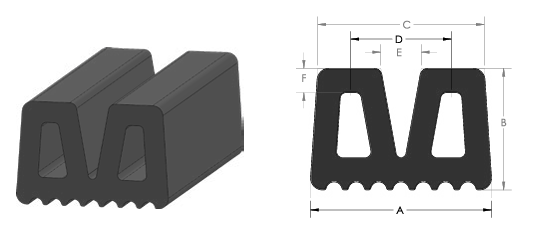

D-D Type Fenders

D-D type fenders, also known as extruded D-fenders, are rubber profiles that are attached to the structure with bolts. Extrusions can be performed virtually to any length. Extrusions can be manufactured in almost any length, then cut and drilled to suit specific applications. Pre-curved sections and custom sizes are available upon request.

Applications

D-D type fenders are used in various applications, including jetties, Pontoon protection, Tugs and workboats, Inland waterways, and general-purpose fendering.

| A | B | C | D | E | ØF | G | H | FLAT BAR | BOLT SIZE | LENGTH |

|---|---|---|---|---|---|---|---|---|---|---|

| 75 | 75 | 35 | 35 | 30 | 15 | 100 | 200 | 35×5 | M12 | 3000 |

| 100 | 100 | 50 | 50 | 30 | 15 | 100 | 200 | 40×5 | M12 | 3000 |

| 125 | 125 | 60 | 60 | 40 | 20 | 125 | 250 | 50×6 | M16 | 3000 |

| 150 | 150 | 75 | 75 | 50 | 20 | 125 | 250 | 60×8 | M20 | 3000 |

| 200 | 200 | 100 | 100 | 50 | 25 | 175 | 350 | 80×10 | M24 | 3000 |

| 250 | 250 | 125 | 125 | 60 | 30 | 175 | 350 | 90×12 | M24 | 3000 |

| 300 | 300 | 150 | 150 | 60 | 30 | 175 | 350 | 110×12 | M24 | 3000 |

| 350 | 350 | 175 | 175 | 75 | 30 | 175 | 350 | 130×15 | M30 | 3000 |

| 400 | 400 | 200 | 200 | 75 | 35 | 175 | 350 | 150×15 | M30 | 3000 |

| 500 | 500 | 250 | 250 | 90 | 45 | 200 | 400 | 180×20 | M36 | 3000 |

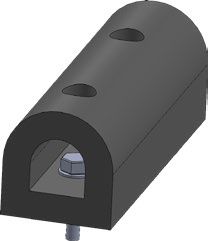

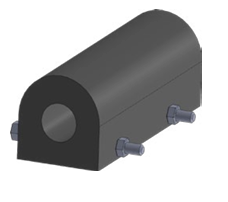

D-O Type

Diode expertly manufactures D-series fenders with both cylindrical and D-shaped bores to meet a variety of mounting requirements. Specifically engineered for tugs and barges, these fenders are built to deliver exceptional long-term durability in applications that experience repeated compression cycles during pushing service. They boast outstanding physical characteristics essential for managing high loads encountered at both initial contact and throughout the entire service cycle.

| A | B | C | ØD | E | F | G | H | Flat Bar | Bolt Size | Length |

|---|---|---|---|---|---|---|---|---|---|---|

| 75 | 75 | 35 | 10 | 25 | 10 | 100 | 200 | 35×5 | M10 | 3000 |

| 100 | 100 | 50 | 15 | 25 | 10 | 100 | 200 | 50×6 | M12 | 3000 |

| 125 | 125 | 60 | 20 | 30 | 12 | 125 | 250 | 50×6 | M12 | 3000 |

| 150 | 150 | 75 | 25 | 30 | 12 | 125 | 250 | 60×8 | M16 | 3000 |

| 200 | 200 | 100 | 25 | 45 | 15 | 175 | 350 | 80×10 | M20 | 3000 |

| 250 | 250 | 125 | 25 | 50 | 15 | 175 | 350 | 100×10 | M24 | 3000 |

| 300 | 300 | 150 | 35 | 60 | 15 | 175 | 350 | 110×12 | M24 | 3000 |

| 350 | 350 | 175 | 35 | 70 | 15 | 175 | 350 | 120×12 | M30 | 3000 |

| 400 | 400 | 200 | 35 | 80 | 15 | 175 | 350 | 130×15 | M30 | 3000 |

| 500 | 500 | 250 | 45 | 100 | 30 | 200 | 400 | 130×15 | M36 | 3000 |

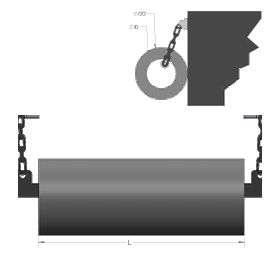

Bar Fender

All fender bars are designed to withstand high impacts and are ideal for a broad range of general-purpose applications.

Applications

Their applications range from ferry berths to bumpers on barges. The vulcanized internal steel plate provides strong fixing points and helps reduce bending moments in the bolts.

| W | H | L | A | B | ANCHORS |

|---|---|---|---|---|---|

| 150 | 150 | 1000 | 250 | 500 | 2 × M24 |

| 150 | 150 | 1500 | 250 | 500 | 2 × M24 |

| 150 | 200 | 1000 | 250 | 500 | 2 × M24 |

| 150 | 200 | 1500 | 250 | 500 | 3 × M24 |

| 200 | 200 | 1000 | 250 | 500 | 3 × M30 |

| 200 | 200 | 1500 | 250 | 500 | 3 × M30 |

| 200 | 250 | 1000 | 250 | 500 | 3 × M30 |

| 200 | 250 | 1500 | 250 | 500 | 3 × M30 |

| 200 | 300 | 1000 | 250 | 500 | 3 × M30 |

| 200 | 300 | 1500 | 250 | 500 | 3 × M30 |

Wing-Type Fender

Wing-type fenders provide high energy absorption, making them suitable for tugs, barges, and other service vessels. Their cross-sectional design enables secure mounting and provides full surface coverage. Specifically designed for vessel installation, wing-type fenders combine the energy absorption benefits of a cylindrical shape with the practicality of wing mounting. They are also commonly used on pilot boats, heavy tugs, barges, and ferries.

| A | B | C | D | LENGTH |

|---|---|---|---|---|

| 120 | 65 | 15 | 25 | 2000 |

| 140 | 45 | 15 | 20 | 2000 |

| 160 | 100 | 25 | 50 | 2000 |

| 177 | 80 | 20 | 38 | 2000 |

| 180 | 100 | 25 | 50 | 2000 |

| 215 | 150 | 30 | 75 | 2000 |

| 245 | 150 | 30 | 75 | 2000 |

| 280 | 200 | 40 | 100 | 2000 |

| 320 | 200 | 40 | 100 | 2000 |

| 330 | 250 | 50 | 125 | 2000 |

| 350 | 200 | 40 | 100 | 2000 |

| 370 | 250 | 50 | 125 | 2000 |

| 410 | 250 | 50 | 100 | 2000 |

| 410 | 250 | 50 | 125 | 2000 |

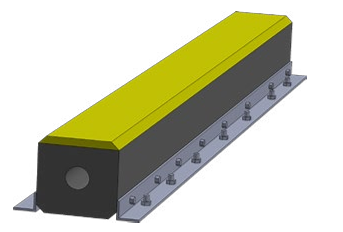

UHMW-PE- Rubber Fenders

UHMW-PE–Rubber fenders are produced using advanced molecular bonding technology, combining the energy-absorbing properties of rubber fenders with the low-friction advantages of a polyethylene surface.

Key Benefits

The UHMW-PE face provides a low-friction, hard-wearing, and durable contact surface. The rubber elements are manufactured from marine-grade compounds, offering high resistance to ozone degradation, UV radiation, and waterborne oil pollution.

Applications

UHMW-PE–Rubber fenders are ideal for most side fendering and guiding applications, especially where a simple extruded fender with low shear forces is required. Their low-friction properties reduce wear on the fender and the vessel. These fenders are well-suited for quay structures in tidal areas, allowing ships to rise and fall with the tide without causing damage to the fender.

SQ-1 FENDER

| A | B | C | T | ØD | E | F | G | H | Flat Bar | Bolt Size | Length |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 100 | 100 | 30 | 20 | 15 | 10 | 100 | 200 | 50 | 50×6 | M12 | 1000 |

| 150 | 150 | 65 | 20 | 20 | 12 | 100 | 200 | 60 | 60×8 | M16 | 1500 |

| 200 | 200 | 75 | 25 | 25 | 20 | 100 | 200 | 80 | 80×10 | M20 | 2000 |

| 250 | 250 | 100 | 25 | 30 | 20 | 100 | 200 | 100 | 100×10 | M24 | 2500 |

| 300 | 300 | 125 | 30 | 30 | 20 | 100 | 200 | 100 | 110×12 | M24 | 3000 |

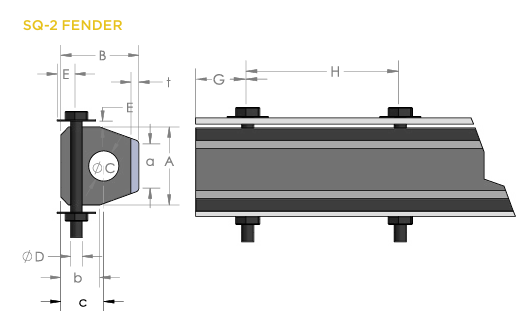

SQ-2 FENDER

| A | B | C | T | ØD | E | F | G | H | Flat Bar | Bolt Size | Length |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 80 | 80 | 42 | 60 | 40 | 10 | 15 | 25 | 100 | 45×6 | M12 | 1000 |

| 100 | 100 | 54 | 70 | 56 | 10 | 15 | 25 | 100 | 50×6 | M12 | 1500 |

| 150 | 150 | 78 | 80 | 65 | 12 | 15 | 25 | 100 | 60×8 | M16 | 2000 |

| 200 | 200 | 92 | 90 | 80 | 20 | 15 | 25 | 100 | 80×10 | M20 | 2500 |

| 250 | 250 | 108 | 100 | 95 | 20 | 15 | 25 | 100 | 100×10 | M24 | 3000 |

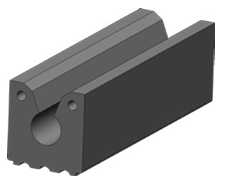

M-Type Fender

M-type fenders are installed on the bows of ocean-going vessels and tugs to protect the hull from damage during heavy-duty operations. They are mounted in a manner similar to keyhole fenders.

Features

- Grooved for extra grip

- Heavy-duty design

- Triple leg attachment

- Fits around tight bends

Applications

- Pontoon Protection

- All kinds of tugs

| A | B | C | OD | E | F | ØPIN | FLATBAR | LENGTH |

|---|---|---|---|---|---|---|---|---|

| 400 | 200 | 40 | 23 | 50 | 150 | 20 | 100×15 | 2000 |

| 500 | 250 | 50 | 27 | 60 | 190 | 24 | 125×20 | 2000 |

| 600 | 300 | 60 | 33 | 70 | 230 | 30 | 150×20 | 2000 |

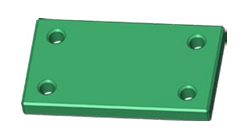

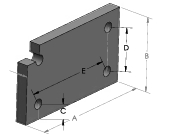

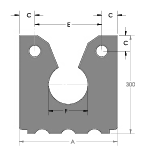

UHMW-PE- Fender Plates

UHMW-PE fender plates are durable pads designed for quays where small vessels are moored, protecting both the quay face and the ship from abrasion. These plates offer high wear resistance and require minimal maintenance, as they do not split or rot and are highly resistant to marine borer infestation.

Options

UHMW-PE fender plates can be manufactured and machined to match specific panel sizes. They can also be supplied with pre-drilled holes and chamfered edges for easy installation.

| A | B | C | T | D | E | Anchors |

|---|---|---|---|---|---|---|

| 1000 | 500 | 100 | 50 | 300 | 800 | 4×M20 |

| 600 | 150 | 450 | 700 | |||

| 750 | 100 | 300 | 650 | |||

| 1500 | 500 | 100 | 50 | 300 | 800 | 6×M20 |

| 600 | 150 | 450 | 600 | |||

| 750 | 100 | 300 | 650 | |||

| 1000 | 500 | 100 | 75 | 300 | 800 | 4×M20 |

| 600 | 150 | 450 | 700 | |||

| 750 | 100 | 300 | 650 | |||

| 1500 | 500 | 100 | 75 | 300 | 800 | 6×M20 |

| 600 | 150 | 450 | 600 | |||

| 750 | 100 | 300 | 650 | |||

| 1000 | 500 | 100 | 100 | 300 | 800 | 4×M20 |

| 600 | 150 | 450 | 700 | |||

| 750 | 100 | 300 | 650 | |||

| 1500 | 500 | 100 | 100 | 300 | 800 | 6×M20 |

| 600 | 150 | 450 | 600 | |||

| 750 | 100 | 300 | 650 | |||

| 1000 | 500 | 100 | 125 | 300 | 800 | 4×M20 |

| 600 | 150 | 450 | 700 | |||

| 750 | 100 | 300 | 650 | |||

| 1500 | 500 | 100 | 125 | 300 | 800 | 6×M20 |

| 600 | 150 | 450 | 600 | |||

| 750 | 100 | 300 | 650 | |||

| 1000 | 500 | 100 | 150 | 300 | 800 | 4×M20 |

| 600 | 150 | 450 | 700 | |||

| 750 | 100 | 300 | 650 | |||

| 1500 | 500 | 100 | 150 | 300 | 800 | 6×M20 |

| 600 | 150 | 450 | 600 | |||

| 750 | 100 | 300 | 650 |

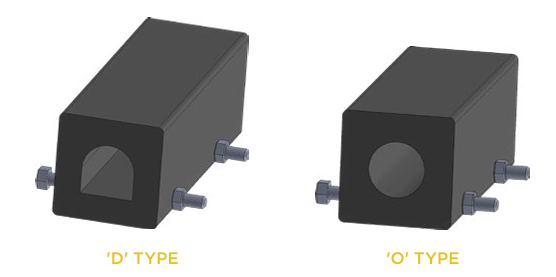

Square Fender

Square-type fenders are used on tugs, barges, and workboats as side belting and protective fenders for heavy-duty applications. These fenders can also be mounted on quays using anchor belts. Square-type fenders are available with D-shaped holes, which can be either rounded, hollow, or solid.

| A | B | C | D | ØD | E | F | G | H | ‘D’ TYPE FLAT BAR | ‘O’ TYPE FLAT BAR | BOLT SIZE | LENGTH |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 75 | 75 | 45 | 45 | 10 | 25 | 30 | 100 | 200 | 35×5 | 35×5 | M10 | 3000 |

| 100 | 100 | 50 | 50 | 15 | 30 | 15 | 100 | 200 | 40×5 | 50×6 | M12 | 3000 |

| 125 | 125 | 60 | 60 | 20 | 40 | 15 | 125 | 250 | 40×5 | 50×6 | M12 | 3000 |

| 150 | 150 | 75 | 75 | 25 | 40 | 25 | 125 | 250 | 50×8 | 60×8 | M16 | 3000 |

| 200 | 200 | 100 | 100 | 25 | 50 | 25 | 175 | 350 | 70×10 | 80×10 | M20 | 3000 |

| 250 | 250 | 125 | 125 | 30 | 60 | 30 | 175 | 350 | 90×12 | 100×12 | M24 | 3000 |

| 300 | 300 | 150 | 150 | 35 | 75 | 35 | 175 | 350 | 100×12 | 110×12 | M24 | 3000 |

| 350 | 350 | 175 | 175 | 35 | 75 | 35 | 175 | 350 | 120×12 | 120×12 | M30 | 3000 |

| 400 | 400 | 200 | 200 | 40 | 75 | 35 | 175 | 350 | 150×15 | 130×15 | M30 | 3000 |

| 500 | 500 | 250 | 250 | 90 | 45 | 200 | 400 | 400 | 180×20 | 150×20 | M36 | 3000 |

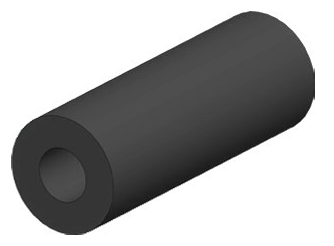

Cylindrical Fender

Cylindrical fenders are simple, versatile, and easy to install, making them ideal for berths accommodating both large and small vessels. The wide range of available sizes allows cylindrical fenders to be closely matched to each application.

Features

- Design: Economical and simple.

- Easy installation and maintenance.

- Abrasion and wear resistant with the presence of thick walls.

Applications

- Bulk cargo berths

- Ferry terminals

- General cargo quays

- Tug havens

- Pontoons and floating structures

- Fishing and workboat berths

| OD | ID | LENGTH |

|---|---|---|

| 100 | 50 | 3000 |

| 125 | 60 | 3000 |

| 150 | 75 | 3000 |

| 200 | 100 | 3000 |

| 250 | 125 | 3000 |

| 300 | 150 | 3000 |

| 400 | 200 | 3000 |

| 450 | 225 | 3000 |

| 500 | 250 | 3000 |

| 600 | 300 | 3000 |

W-Type Fender

W-type fenders are installed on the bows of ocean-going tugs to protect the hull from damage during pushing, pulling, or towage operations. These fenders are mounted in a manner similar to that of keyhole fenders.

Features

- Twin-leg attachment

- Extreme-duty design

- Grooved for extra grip

- Open the bone for easy installation

- Fit around tight bends

Applications

- Icebreakers

- Bridge and pile protection

- Ocean-going tugs

- Large harbor tugs

| A | B | C | D | E | F | K | Ø PIN | FLAT BAR | LENGTH |

|---|---|---|---|---|---|---|---|---|---|

| 320 | 200 | 280 | 180 | 100 | 67 | 50 | 25 | 100×20 | 2000 |

| 400 | 250 | 350 | 220 | 110 | 75 | 55 | 30 | 120×20 | 2000 |

| 480 | 300 | 426 | 269 | 135 | 90 | 65 | 40 | 140×20 | 2000 |

| 500 | 450 | 420 | 255 | 90 | 100 | 75 | 40 | 150×20 | 2000 |

Keyhole Fender

Keyhole fenders are used as an alternative to W-fenders for handling hefty loads. Their keyhole-shaped cross-section is highly durable yet flexible enough to be curved around the hull. This type of fender also allows for simple installation.

Features

- Traditional, proven shape

- Heavy-duty design

- Fits around bends

- Grooved or plain surface

| A | B | C | ØD | E | ØG | Ø PIN | FLAT BAR | LENGTH |

|---|---|---|---|---|---|---|---|---|

| 200 | 200 | 35 | 28 | 130 | 90 | 25 | 100×15 | 2000 |

| 250 | 250 | 50 | 33 | 150 | 100 | 30 | 125×20 | 2000 |

| 300 | 300 | 60 | 33 | 180 | 115 | 30 | 150×20 | 2000 |

| 350 | 350 | 70 | 33 | 210 | 125 | 30 | 175×25 | 2000 |

Reasons for Using UHMWPE Fenders

- High Impact Resistance: UHMWPE Fenders deal with powerful impacts better than other options to shield fixed and floating installations from injury.

- Low Friction Surface: The fender surface wears less on ships and creates more effortless docking without damage.

- Corrosion & UV Resistant: Performs well in harsh marine environments with minimal degradation.

- Lightweight & Durable: The product includes durable strength and simple handling, making it dependable over time.

- Minimal Maintenance: The product needs small maintenance actions, which makes operations less expensive.

Diode Trading EST leads the industry by offering top-quality UHMWPE fenders for optimal vessel and structure defence. The company has a tremendous reputation in the market for the most outstanding deals on UHMWPE Fenders across Saudi Arabia.

Buy High-Quality Marine Fender Manufacturer in Saudi Arabia With Us!

Are you looking for a high-quality marine fender manufacturer in Saudi Arabia? Connect with Diode Trading EST today. We are associated with manufacturers from a renowned company. Our products are designed to provide excellent wear-resistance, maximum impact absorption, and long-term durability. Our products are ideal for marinas, ports, and industrial docking applications. If you are ready to buy the best marine fenders in Saudi Arabia, connect with us today.

Need the Best Dock Fender Boards Manufacturer in Saudi Arabia? Contact Us Today!

If you need the best dock fender boards in Saudi Arabia, contact Diode EST today and get the right quality dock fenders at an affordable cost. Our fenders are widely used in commercial and industrial docks, shipyards, jetties, and commercial docks. The products of Diode Trading EST are made up of high-performance UHMWPE sheets that avoid damage caused by friction or heavy impact. So, don’t wait and connect with Diode Trading EST today.

Seeking the Best Low-Friction Centre Plates Manufacturers in Saudi Arabia? Visit Us Now!

Diode Trading EST is the leading supplier connected to the best low-friction centre plates manufacturers in Saudi Arabia. Our products are designed to enhance sliding performance and reduce drag. Our products are made up of UHMWPE materials. Diode Trading EST is used for cranes, heavy equipment, and marine loading systems. Our centre plates feature lightweight but strong, excellent dimensional stability, superior wear and abrasion resistance. So, why wait? Connect with Diode Trading EST now.

UHMWPE Fender – FAQs

Q1. Where can I buy from a marine fender manufacturer in Saudi Arabia?

A. You can connect with Diode Trading EST and buy the best marine fenders in Saudi Arabia.

Q2. What are the best dock fender boards in Saudi Arabia?

A. The best dock fender boards in Saudi Arabia feature wear resistance, low friction, UV-resistance, impact resistance, and customization.

Q3. Do you supply the dock fender boards manufacturer in Saudi Arabia in bulk for projects in Saudi Arabia?

A. Yes, we supply the dock fender boards manufacturer in Saudi Arabia in bulk for projects in Saudi Arabia.