Uses of Silicone Rubber Sheets

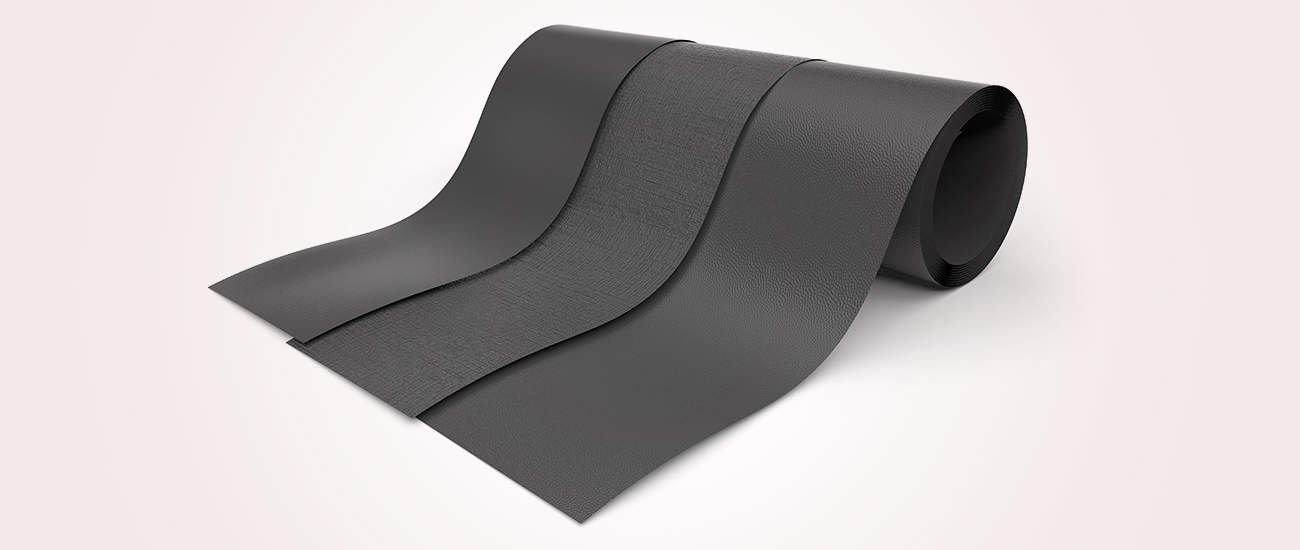

Manufacturers globally choose silicone rubber sheets because they offer the industry three main advantages: versatility, durability, and the capability to withstand severe conditions.

- Automotive Industry: Gaskets, together with seals and insulation, rely on silicone rubber sheets within the automotive industry.

- Medical Applications: Ideal for surgical and pharmaceutical equipment.

- Electrical Industry: Provides insulation in cables and circuits.

- Industrial Sealing: Silicone rubber sheets prove the best option when industrial operations need high-temperature sealing systems.

- Food & Beverage:This sector utilizes the material for safe applications that involve food and beverage packaging.

The experts at successfulPolypropylene Manufacturers In Saudi Arabia believe that these specialized sheets are perfect for added safety, security, and other necessary factors.

Reasons For Increasing Demand For Silicone Rubber Sheets!

Silicone rubber sheets are becoming more popular because they offer extended durability, heat tolerance, and flexible characteristics. The expanding industrial use of these sheets is driving up demand.

- 1. Heat & Weather Resistance:These sheets are ideal for extreme temperatures.

- 2. Chemical Resistance: They are suitable for extensive industrial applications.

- 3. Durability & Flexibility: The quality of these sheets outperforms traditional materials.

- 4. Growing Industrial Use: Preferred by Polymer Manufacturers in Saudi Arabia.

- 5. Reliable Supply: Offered by leading Silicone Rubber Sheet Suppliers in Saudi Arabia.

Available with top Polymer Manufacturers In Saudi Arabia, these specialized Silicone Rubber Sheets have become more popular. Larger industries from all over Saudi Arabia collaborate with the top Polyethylene Suppliers In Saudi Arabia, in addition to reaching well-established manufacturers!

Industry Specific Names

Technical engineering plastic products involve identical names such as high-performance plastic products, thermoplastic engineering products, machinable plastic components, eear-resistant plastic parts, high-strength polymer parts, performance plastics (e.g., POM, PTFE, Nylon, UHMW-PE), custom-engineered plastic solutions, industrial polymer sheets and rods, plastic mechanical parts, functional thermoplastic assemblies, and technical-grade synthetic materials. These products are renowned for their durability, versatility, and ability to resist a wide range of situations.