Technical Specification

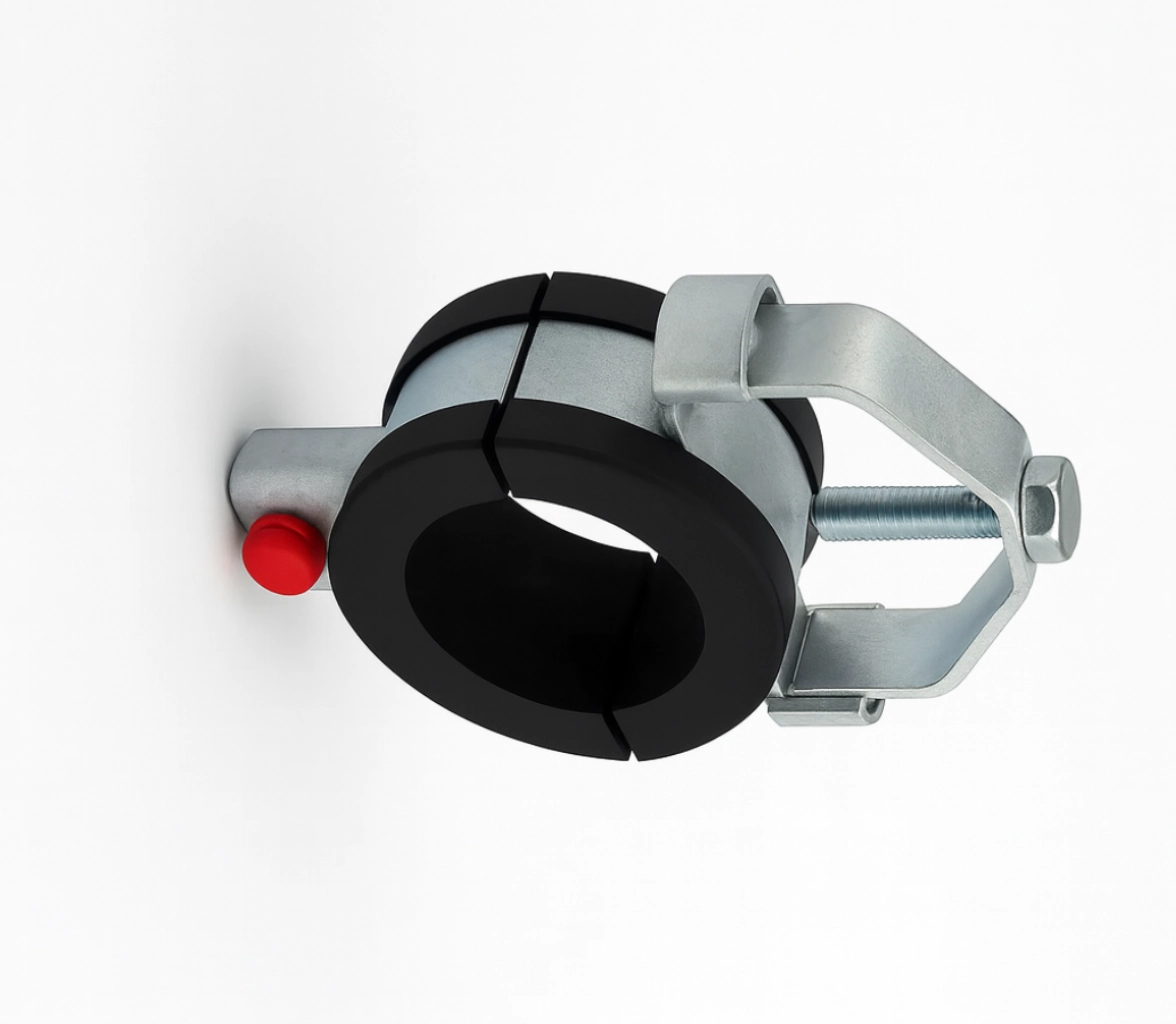

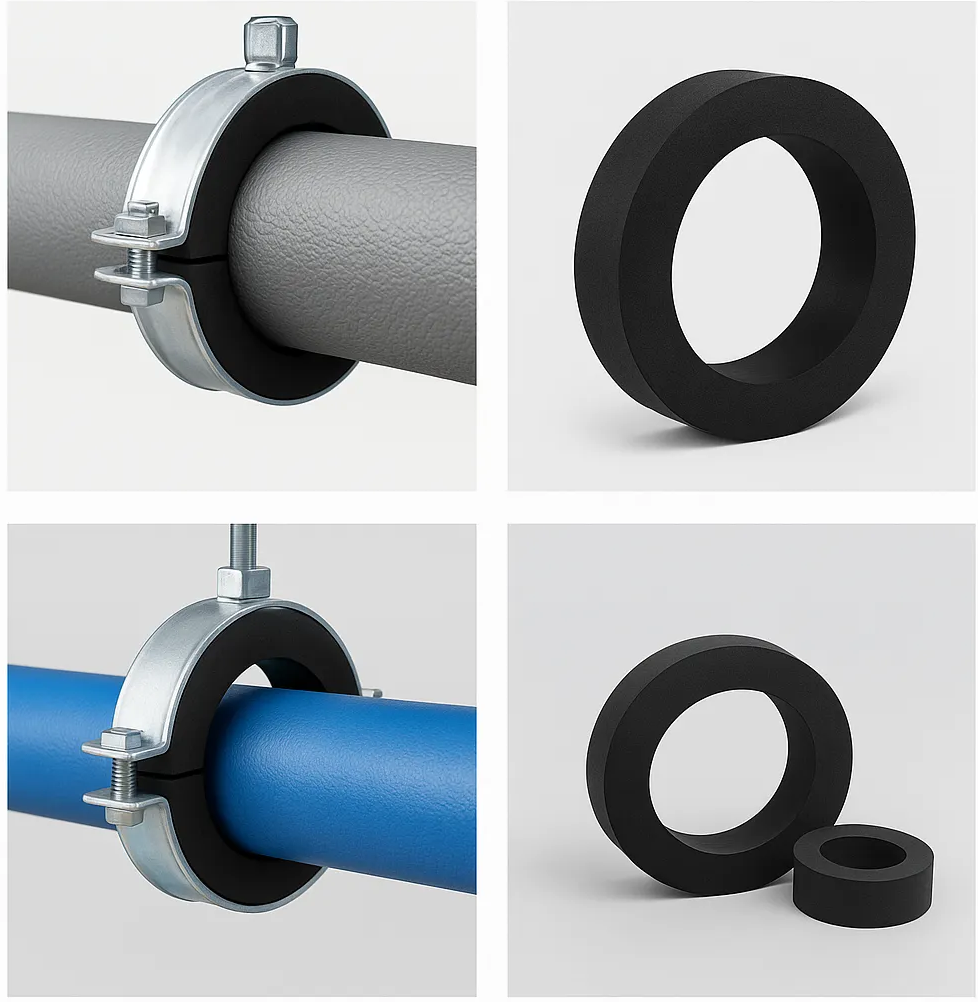

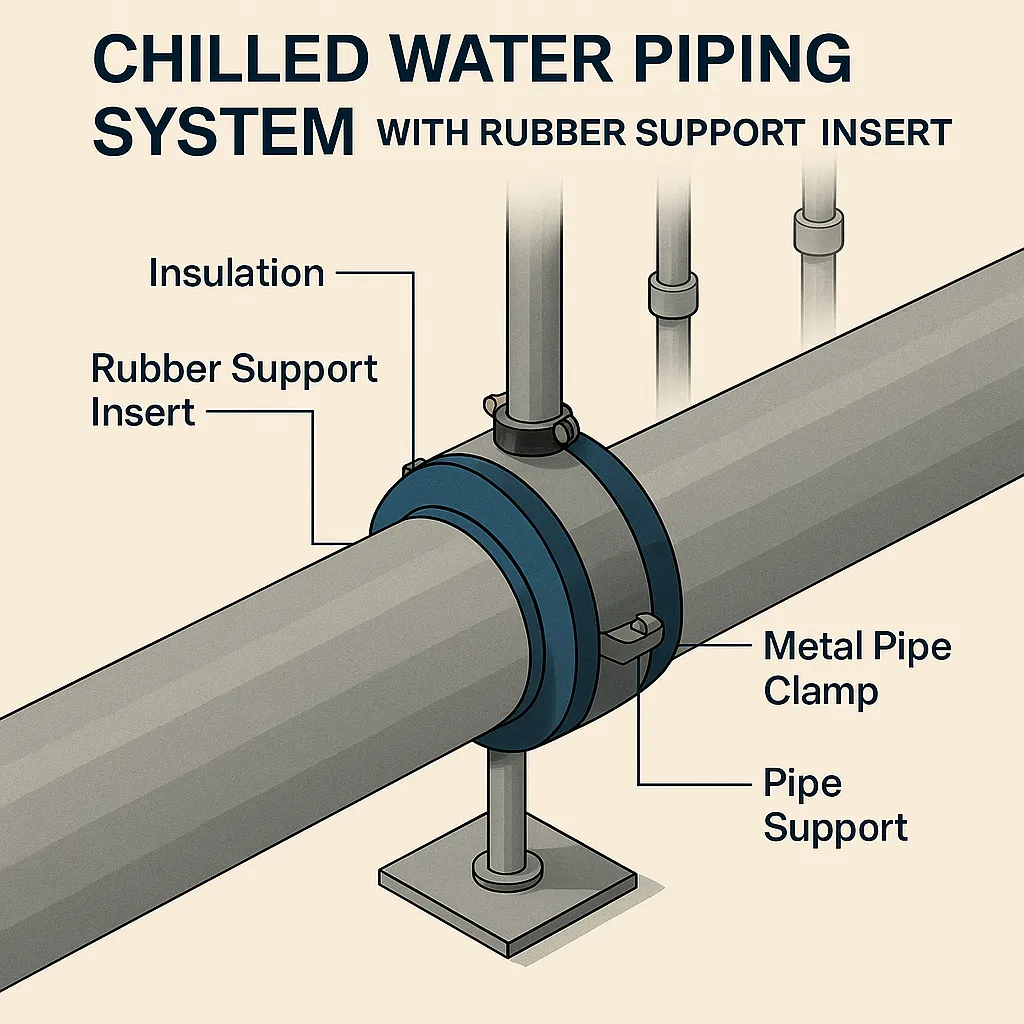

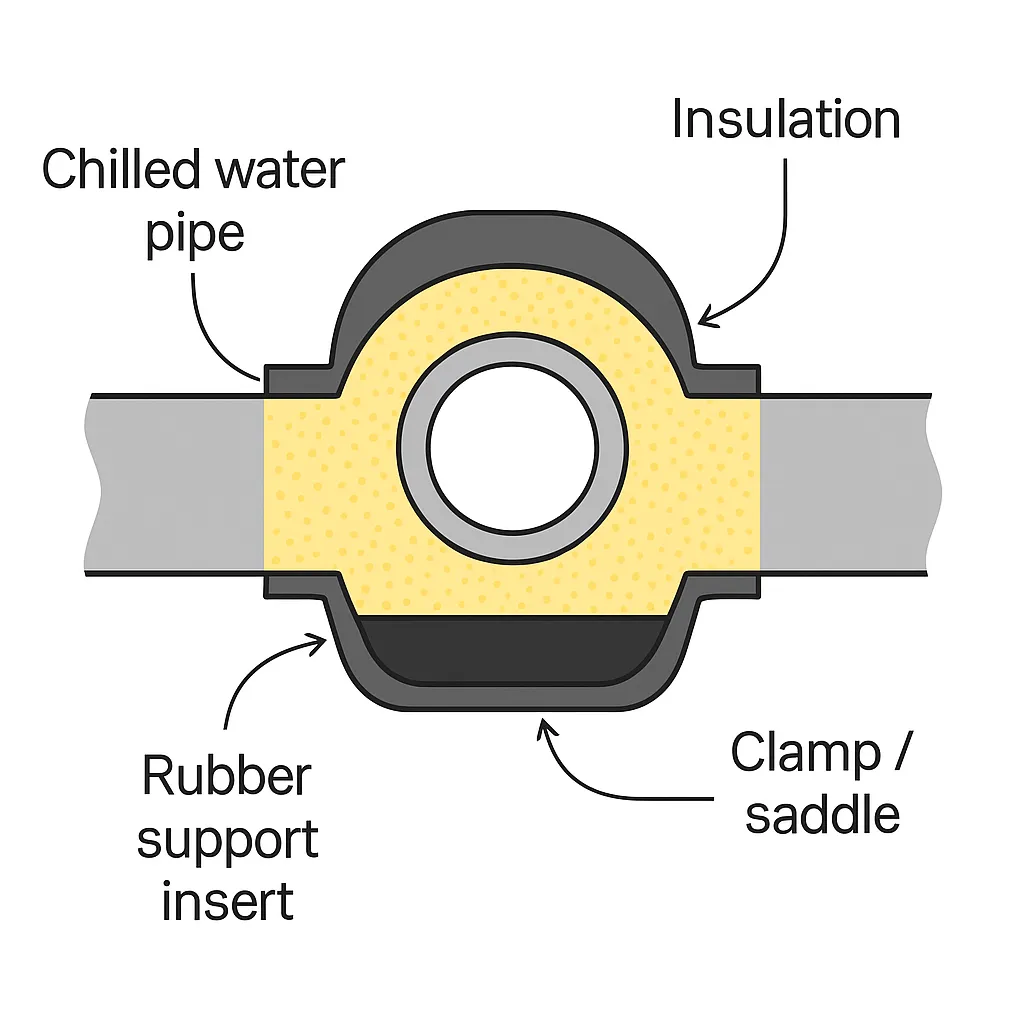

Our high-performance Rubber Support Inserts are precision-engineered for chilled water and HVAC piping systems. Made from high-density EPDM or Neoprene rubber, these inserts provide superior thermal insulation, vibration control, and load-bearing support. They maintain insulation continuity, eliminate condensation, and ensure energy-efficient operation.

- Material: EPDM / Neoprene Rubber

- Density: 200 – 600 kg/m³

- Temperature Range: -35°C to +120°C

- Compressive Strength: 0.5 – 1.5 N/mm²

- Pipe Size Range: DN15 to DN600 (½” to 24”)

- Fire Rating: BS 476 Part 7 Class 1 (optional)

- Finish Options: Galvanized / Stainless Steel Clamp or Saddle

Key Features and Benefits

- Acts as a thermal break to prevent condensation and thermal bridging at pipe supports.

- Reduces vibration and structure-borne noise in HVAC systems.

- Supports heavy pipes with minimal deformation for long-term performance.

- Manufactured from durable EPDM or Neoprene rubber resistant to UV and temperature extremes.

- Prevents corrosion under insulation (CUI) by eliminating moisture buildup.

- Ensures seamless insulation continuity and vapor barrier integrity.

- Quick and easy installation with minimal maintenance required.

Industries and Applications

- HVAC and Building Services – chilled and condenser water systems.

- Commercial Buildings – offices, hospitals, malls, and hotels.

- Industrial Facilities – process cooling and utility piping.

- Data Centers – high-efficiency chilled water systems.

- Pharmaceutical & Clean Rooms – moisture-controlled environments.

- Infrastructure Projects – airports, metros, and campuses.

Material Testing and Performance (ASTM Standards)

| Sl No | Property | Test Method | Condition | Specification |

|---|---|---|---|---|

| 1 | Base Polymer | — | — | NR / SBR |

| 2 | Specific Gravity | ASTM D 1817 | Before Ageing | 1.50 ± 0.05 g/cm³ |

| 3 | Hardness | ASTM D 2240 | Before Ageing | 80–90 Shore A |

| 4 | Tensile Strength | ASTM D 412 | Before Ageing | ≥ 65 Kg/cm² |

| 5 | Elongation at Break | ASTM D 412B | Before Ageing | ≥ 175% |

After Ageing Test (ASTM D 573)

- Change in Hardness: ≤ +10 Shore A (70°C for 72 hours)

- Change in Tensile Strength: ≤ -25% (70°C for 72 hours)

- Change in Elongation: ≤ -25% (70°C for 72 hours)

- Compression Set: ≤ 30% (ASTM D 395, 24 hours)

Installation Guidelines

- Ensure the rubber insert thickness matches the insulation thickness.

- Place the insert between the pipe and support clamp before tightening.

- Seal insulation joints and vapor barrier properly to prevent condensation.

- Use bonded metal saddles for heavy-duty or large-diameter pipes.

Quality Assurance and Compliance

- Manufactured under ISO 9001 certified quality systems.

- Complies with ASHRAE and SMACNA guidelines for insulated supports.

- Fire-rated and RoHS compliant materials available.

- Tested to international ASTM standards for mechanical performance.

Key Features & Benefits

- Thermal Break – Prevents condensation and thermal bridging at support points.

- Durable Material – Made from high-density EPDM or Neoprene rubber for long life.

- Load Bearing Strength – Withstands heavy pipe loads without deformation.

- Vibration & Noise Control – Minimizes structure-borne noise and vibration.

- Condensation Protection – Prevents “sweating” and corrosion under insulation (CUI).

- Easy Installation – Fits standard pipe clamp and hanger systems.

- Insulation Continuity – Matches thickness of pipe insulation for complete vapor barrier integrity.

Technical Specifications

| Parameter | Details |

|---|---|

| Product Name | Rubber Support Insert |

| Application | Chilled Water & HVAC Piping Systems |

| Material | EPDM / Neoprene Elastomer |

| Density | 200 – 600 kg/m³ |

| Temperature Range | -30°C to +110°C |

| Compressive Strength | 0.5 – 1.5 N/mm² |

| Pipe Size Range | DN15 to DN600 (½” to 24”) |

| Insulation Compatibility | Nitrile, Elastomeric, Phenolic, or PU Foam |

| Surface Finish (Optional) | Galvanized or Stainless Steel Clamp/Saddle |

| Fire Rating | BS 476 Part 7 Class 1 or equivalent (optional) |

| Color | Black or Grey |

| Customization | Available for non-standard sizes and thicknesses |

The Best Rubber Support Insert Manufacturer in Saudi Arabia

The purpose of rubber support inserts is to keep low-density pipe insulation from being crushed at hanger locations. When pipe insulation runs through a clevis hanger, roller, anchor, guide, or strut system, appropriate pipe insulation supports and shields are essential for preserving thermal performance and system integrity. Heat or moisture cannot be directly transferred from the shield to the pipe thanks to these supports. At Diode Trading EST, we provide the best rubber support insert in Saudi Arabia to help you with your project.

Get The Best Rubber Support Insert for Chilled Water in Saudi Arabia at an affordable price.

Acquire the best-quality rubber support inserts for the chilled water system from Saudi Arabia only at Diode Trading EST. These inserts are designed to provide superior load distribution and control vibrations, effectively preventing damage to the pipes. Our products are not only standards-compliant but also economical. Choose Diode Trading EST for trusted solutions and reliable supply across Saudi Arabia.

Why Choose Us?

Diode Trading EST is committed to providing high-quality, long-lasting goods, competing on price, and ensuring rapid delivery services in the Kingdom of Saudi Arabia. Our company takes pride in our unswerving commitment to the best standards of quality and customer satisfaction. As a reliable partner to our clients in the contracting, consulting, and development sectors, we are eager to provide innovative solutions for rubber support inserts that meet the varied demands of the construction sector.

Rubber Support Insert for Chilled Water & HVAC Pipes – FAQs

Q1. Where are rubber support inserts commonly used?

A. Rubber support inserts are used in automotive, electronics, and general construction for cushioning and isolation. Still, they are mainly used in HVAC and piping systems to prevent insulation crushing at supports, maintain thermal performance, and dampen vibration.

Q2. Are rubber support inserts suitable for chilled water systems?

A. To ensure thermal performance, prevent insulation from being crushed at support points, and reduce vibration and noise in HVAC and piping systems, rubber support inserts are highly appropriate. They are frequently used in chilled water systems.

Q3. How long do rubber support inserts last?

A. Rubber support inserts usually have a lifespan of 3 to 12 months in over-the-counter insoles. However, custom-made orthotics can last several years. The lifespan of support inserts can vary greatly.